LEAK DETECTION

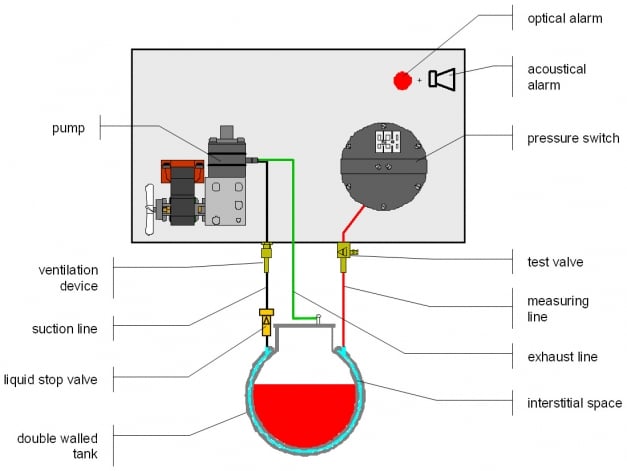

Overpressure leak detector DL-325

Leakdetection system to detect and indicate leaks in doublewalled tanks. The leakdetector DL-325 can monitor several underground tanks or one aboveground tank.

Leaks in one of the walls will be detected and indicated by an optical and audible alarm before any stored product can enter the environment.

A class I leak detection system, with the highest environmental protection level in accordance to the European standard EN 13160.

Here you can find:

- SGB DL-325

- SGB VL-330

- Cabinet KS1449

- GOK LAG2000A

- Sight glass

Monitoring principle:

The pump in the leakdetector creates an operational overpressure in the interstitial space. This operational pressure is higher than the pressure of the stored product/ground water to the low point of the interstice. In case of a leak, the compressed air will escape through the leak. This prevents product or groundwater entering the interstitial space. Any minor unavoidable untightness is compensated by the system automatically.

If the volume flow of air escaping from the interstitial space is higher than the limited volume flow of the pressure pump, the pressure will drop to the alarm pressure. An optical and audible alarm will be released. The compressed air in the interstitial space is dried by the dry filter mounted to the leak detector. Therefore a condensation of water in the interstitial space is prevented. An inadmissible overpressure in the interstitial space is prevented by a pressure relief valve.

Liquids to be monitored:

• Water polluting liquids

• e.g.: petrol/gasoline, heating oil, diesel, lye, acid

For the monitoring of:

• double-walled tanks with a test pressure of the interstitial space of min. 400 mbar (e.g. applicable tanks in accordance to the EN-standard). Maximum pressure of the stored liquid to the bottom of the tank: 230 mbar

• tanks with permeable inner wall only for liquids with flash point above 55°C.

Underpressure leak detector VL-330

Leakdetection system to detect and indicate leaks in CGH double-walled tanks. Every leak in one of the walls will be indicated by an optical and audible alarm before liquid enters the environment.

Class I-system in accordance to the European standard EN 13 160.

Monitoring principle:

The pump in the leak detector creates a operational underpressure in the interstitial space. Any minor unavoidable untightness is compensated by the system automatically. In case of a leak, air, groundwater or product is sucked into the interstitial space. If the volume flow of air entering the interstitial space is higher than the limited volume flow of the vacuum pump, the pressure will rise to the alarm underpressure.

Groundwater or stored product is sucked into the interstitial space. When the interstitial space is filled up, the liquid enters the liquid stop valve, which closes then. No further underpressure can be produced. Some more liquid will be sucked into the measuring line, causing a rise in pressure to the alarm underpressure. The optical and audible alarm is released.

Liquids to be monitored:

Water polluting liquids :

![]() • Model VL-330: with a flash point > 55° Celsius; (e.g. Diesel, heating oil)

• Model VL-330: with a flash point > 55° Celsius; (e.g. Diesel, heating oil)

![]() • Model VLXE: with a flash point < 55° Celsius (e.g.: gasoline/petrol, jet fuel)

• Model VLXE: with a flash point < 55° Celsius (e.g.: gasoline/petrol, jet fuel)

![]() • Specific chemicals in accordance to chemical resistance of the leak detector. Different materials to realise chemical resistance are available.

• Specific chemicals in accordance to chemical resistance of the leak detector. Different materials to realise chemical resistance are available.

Approved for the use together with:

![]() • double-walled horizontal tanks (e.g. EN 12285)

• double-walled horizontal tanks (e.g. EN 12285)

![]() • single-walled horizontal or rectangular tanks equipped with a lining (e.g. DIN 6625 or similar)

• single-walled horizontal or rectangular tanks equipped with a lining (e.g. DIN 6625 or similar)

![]() • double-walled ball shaped tanks

• double-walled ball shaped tanks

![]() • upright standing tanks (e.g. DIN 6618/2)

• upright standing tanks (e.g. DIN 6618/2)

SGB VL-330: Data sheet - Download PDF

Cabinet KS1449

- Cabinet for outdoor installation - SGB DL-280 and SGB VL-330

- Available with 20 watt heater and thermostat.

- With heater - the system can be used for outdoor temperatures down to approx. -30 °C

- Width x Height x Depth = 400 x 600 x 200 mm

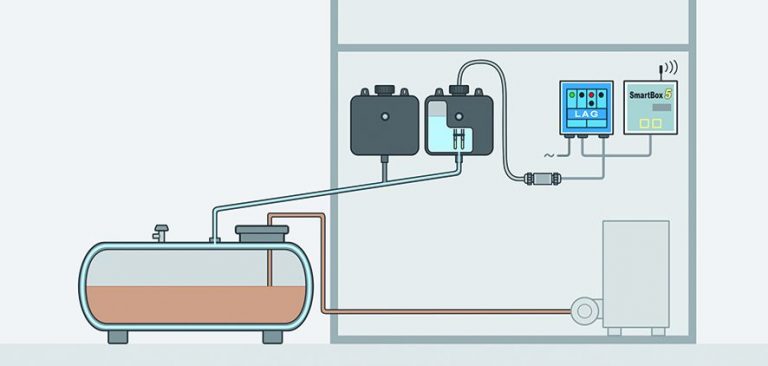

GOK LAG2000A

Leak detector type LAG 2000 to indicate leaks on double-walled above-ground and underground tanks

- Leakdetector for systems containing liquids

- Incl. control box with built-in acoustic and visual alarm function and relay output

- Expansion unit with liquid sensor

Sight glass

- For aboveground double-walled tanks containing water-polluting liquids.

- Application under atmospheric conditions for steel tanks and double-walled tanks with approval for leak detectors.

- No power required